Nyloil®

- Can’t afford a standard 8’ x 4’ sheet of Precision Board?

- Your job does not require a large piece of PB?

- At Norva Plastics we can supply you with any size or length of PB

material. Whether you have a small or a large project, we can provide

you the lowest price and at the right quantity that you need to fill your

order. - Sizes: ½”, ¾”, 1”, 1.5”, 2”, 3”

- Densities: 15, 18 & 30 lbs

Full-service plastics fabricator and supplier of plastic materials

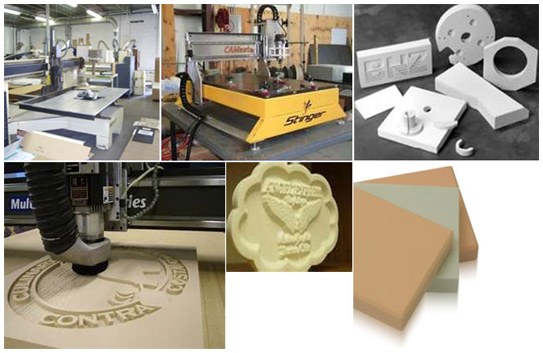

Norva Plastics has been a full-service plastics fabricator and supplier of plastic materials. With over half a century in the business, we can tackle just about any job with confidence that comes from experience. From a tough prototype to long-run production, whatever your requirement, contact the experienced plastics fabricators first at Norva Plastics.

Norva Plastics provides many services relating to plastics and similar materials. We have 3 high precision CNC machines in house to handle high production jobs or for quick prototype jobs. We also do custom fabrication and also offer vacuum forming services. So contact us now! We look forward to serving you.